|

|

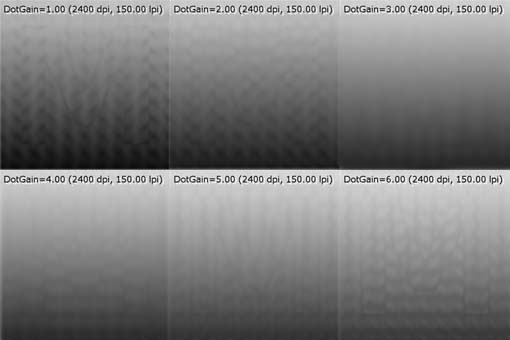

Printed tests for determination of required dot gain compensation |

Lesson 3

Let's define the value required for dot gain compensation at printing.

1. Start the program MATRIX®.

2. Pass to the menu "Parameters".

3. Set the value of ruling 150 lpi.

4. Set the value of the resolution 2400 dpi.

5. Set the angle of screening 45 degrees.

6. Pass to the menu "Generation".

7. In the menu "Dot Gain Test" set the initial value 1.0, a step 1.0, and the final value 6.0.

8. Generate the tests.

9. Import the generated files into any graphic editor and arrange them on one sheet. The imported images cannot be compressed or dragged out.

10. Generate a print-file for production of a photopositive or a typographic plate. At generation it is impossible to use an option of automatic reduction of the resolution of images.

11. Print the tests by the offset machine, using different grades of paper. Watch the observance of all technological processes.

|

|

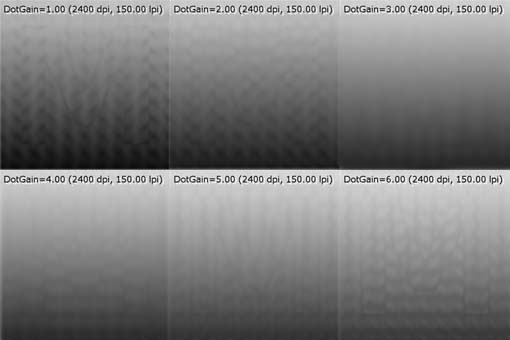

Printed tests for determination of required dot gain compensation |

12. Note the positions with the smoothest background on the printed samples. The stains and the letter "M" should not be appreciable.

13. In further work use the values of dot gain compensation specified on the marked positions.

14. Repeat the tests if there were any changes in the production chain (change of the equipment or materials).

|

|

|

Correctly chosen value of compensation |

Badly adjusted manufacturing technology |

• The function "Dot Gain Compensation" cannot compensate for the light-shorting of the fine halftone dots, therefore it is necessary to watch for the gauging of the exposing and developing machines. Do not use too high values of ruling LPI and typographic plates of poor quality..

• The deviation from the required value of compensation will not be as appreciable at usual works as on the printed tests..

• In offset printing the quality of the image depends on the gauging of the device for the production of photopositives or plates (thus the established linearization has no value, it is desirable that the device being used would demand minimal linearization), on the type of materials used (we recommend a film of Hard Dot class and high-quality typographic plates), on the adjustment and technical condition of a press (ink feed, tightness of cylinders, humidifying, replacement of wearing elements).